Polyethylene (PE) pipe

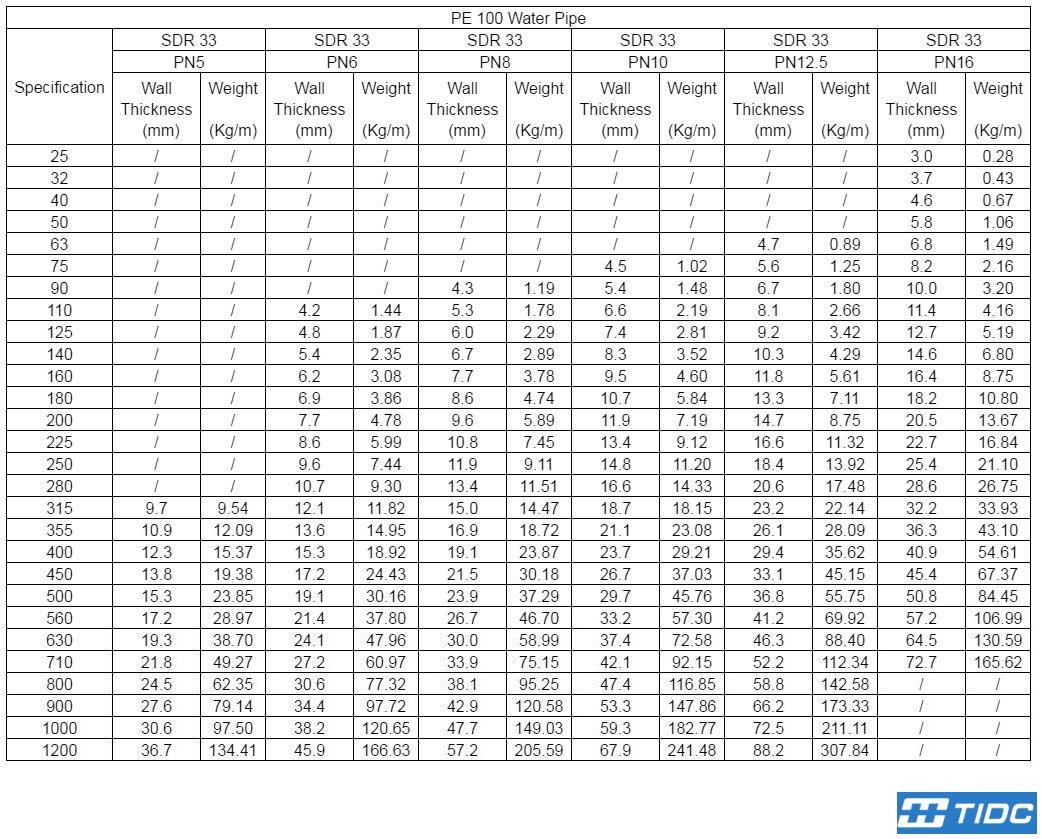

Process:

We provide High Density Polyethylene Pipe (HDPE Pipe), HDPE Plastic Pipe and HDPE Irrigation Pipe, which is available in all standards like ISI-4984, ISO-4427, DIN-8074 and various grades like PE-63, PE-80, PE-100 and newly invented PE 100 material that is approved by international agencies such as Bodycote, Germany. Made using 100% virgin grade HDPE compounds, our range of pipe have an average life of more than 50 years under normal working conditions. These High Density Polyethylene Pipe, HDPE Plastic Pipe and HDPE Irrigation Pipe are available in sizes ranging from 20mm to 1000mm OD and pressure varying from 2.5 Kg/cm2 to 20 Kg/cm2. We offer customization on our range as per the specifications of our clients.

Specification:

Properties:

1. High impact and crack resistance.Very high resistance to direct sunlight (UV resistance for long time) this is supplied by ultraviolet light resistance agent mixed to the PE raw material. There is no need to take protection precautions at the time of installation like cathodic protection.

2. Availability of connection at a place out of the trench. Advantage of being not affected from earth movements like landslide, earthquakes PE pipes require fewer fittings for connection because they are elastic and in many place they do not require connection where the other types do. Because PE pipes are bendable with aradius of 20 times of its out diameter. The other pipe type do not have this advantage.

3. Advantage of mobilization of the PE pipe production facilities. This enable very big saving in transport costs for projects where large diameter pipes are required.

4. Advantage of higher durability & advantage of easy installation and transport without material loss.

5. PE pipes do not require concrete block at the place like bending and tee separations.

6. PE pipes do not require welding characteristics.

7. Very good adoption to earth movements.

8. Many different pressure resistance option, PE pipe can be produced resistant to 12 different pressure class from 2.5 bar up to 32 bar.

9. High resistance to chemical, not affected from corrosion , decaying and abrasion.

10. Advantage of perfect leak proof no crack no break and no deformation.

11. Advantage of safe application in irregular surface like sea, river, lake passages at place where there can be no sockets.

12. Availability of more than one connection method (butt welding. Electro fusion welding, push fit sockets).

13. Advantage of having perfectly smooth internal surface because of this advantage of PE pipes in comparison to the other pipe types. This brings considerable saving in the overall cost of the line and the services costs.

14. PE pipes have the advantage of very long service life under severe conditions.

15. PE pipes are light in weight, which enable the installation with high speed at places.

16. PE pipes are elastic, which is a big advantage during the earthquake or any other earth movements. This characteristics also big advantage in transport (coiling up to 125 mm diameter and in installation costs.

Applications:

1. Urban and rural water supply networks

2. Urban and rural sewage networks

3. Drainage networks

4. Fluid systems and industrial sewage

5. Pressurized irrigation systems (Drip and sprinkler irrigation system)

6. Moving irrigation systems

7. Telecommunication cable coverings / optical fiber coverings

8. Power cable covering

9. Metal pipe covering

10. Ventilation channels