Steel Mesh Reinforced Polyethylene (PE) Pipe

Process:

Steel Mesh Reinforced Polyethylene (PE) pipes is a new kind of pressure pipe, was invented by HTIDC. It is made by combining metal-shaped steel reinforcement with polyethylene through extrusion technology. The steel mesh is made by continuously winding and welding the transverse wires spirally to the longitudinal wires to form a continuous tube-like mesh.

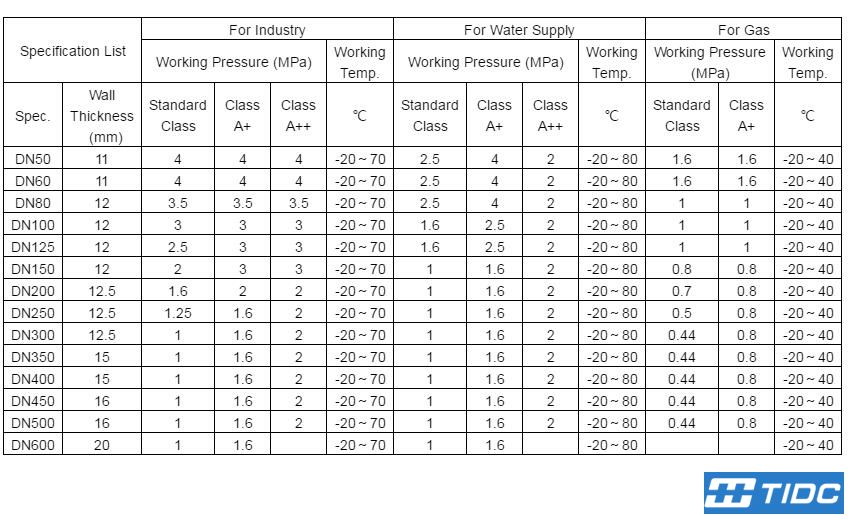

Specification:

Properties:

1. Polyethylene Material

The stuffing material of Steel Reinforced PE pipe and fitting is PE 80/PE100(piping class).

(Characteristics of PE 80/PE100 (piping class) material)

Characteristics | Test Standard | Unit | Result |

Melt Flow Index(5Kg,190℃) | ASTM D 1238 | G/10min | 0.56 |

Density | ASTM D 792 | G/cm3 | 0.954 |

Tensile Yield Strength | ASTM D 638 | Kg/cm2 | 230 |

Tensile Fracture Strength | ASTM D 638 | Kg/cm2 | 370 |

Tensile & Elongation Ratio | ASTM D 638 | % | ≥600 |

Brittleness Temperature | ASTM D 746 | ℃ | ≤-70 |

Linear Expansion Coefficient | DIN 53752 | K-1 | 1.3x10-4 |

ESCR (F50) | ASTM D 1689 | HR | >2000 |

Thermal Stability | ISO 10837 | min | >20 |

Grade | ASTM D 4131(B) | PE 80 | |

Long-term Hydrostatic Strength | ISO 9080 | MPa | 9.33 |

Short-term Hydrostatic Strength | ASTM D 4131 | HR | >165 |

2. The pressure reduction factors shall apply to pipes to be used at different temperatures

(Conveying water lower than 20℃ does not play adverse effects on the performance of the pipe. The working pressure at higher temperature shall be obtained by multiplying the nominal pressure given in table 1, with the pressure reduction factors given as below.)

Temperature t,℃ | 0<t≤20 | 20<t≤30 | 30<t≤40 | 40<t≤50 | 50<t≤60 | 60<t≤70 | 70<t≤80 |

Pressure reduction factors | 1 | 0.95 | 0.90 | 0.86 | 0.81 | 0.70 | 0.60 |

3. Technical parameters of the Steel Mesh Reinforced PE pipe

Linear expansion coefficient (1/℃) | 35.4-35.9x10-6 |

Heat reversion (%) | ≤0.4 |

Out-of roundness | ≤5 |

Elasticity modulus(GPa) | 2-3 |

Thermal conductivity at 20℃ | 0.43 |

Surface resistance (Ω) | >1013 |

Volume resistance(Ω.cm) | >1016 |

Electric strength (kv/cm) | 700 |

Absolute roughness (mm) | 0.01 |

Vicat softening temperature (℃) | 117.9 |

Tensile yielding strength (MPa) | 22-23 |

Shore hardness | 60 |

Impact strength (Notched)(J/mm2) | 15 |

Bend creep modulus (MPa) | a |

4. Performance for Steel Mesh Reinforced HDPE Pipe

No. | Item | Performance | |

1 | Stability under pressure | No cracking | |

2 | Contractility rate of portrait size (110℃ 1h) % | ≤0.4 | |

3 | O.I.T(200℃)/min | ≥20 | |

4 | Short term hydrostatic strength test | Temp: 20, Time: 100h, Pressure: nominal pressure×1.5 | No cracking and leakage |

Temp: 80 Time: 165h Nominal pressure×1.5×0.6 | No cracking and leakage | ||

5 | Burst test | Bust pressure≥nominal pressure×3 | |

6 | Weathering resistance test(accumulated reception≥3.5 kMJ/m2) | Still meet the performance requirement of Item 3 and 4 in this Table | |

CE Certification:

EN12201 Certification:

Industrial safety certification:

GOST :